Knowing how to remove a stripped screw is an essential repair skill for homeowners, DIYers, mechanics, and electronics users alike. A stripped screw—where the screw head is damaged and the screwdriver can no longer grip—can instantly stop a project, whether you’re repairing furniture, working on a laptop, or fixing household hardware.

Stripped screws are common because of worn tools, incorrect screwdriver sizes, excessive torque, corrosion, or soft materials like plastic and wood. The good news is that most stripped screws can be removed safely using the correct technique, patience, and the right tools—without damaging the surrounding material.

This in-depth guide explains how to remove a stripped screw in multiple real-world situations, including wood, metal, plastic, laptops, and cases where only a screwdriver is available. Each method is explained carefully with safety considerations, tool choices, and practical tips based on professional repair experience.

Understanding What a Stripped Screw Is and Why It Happens

Before learning how to remove a stripped screw, it’s important to understand what stripping actually means. A stripped screw occurs when the grooves in the screw head (Phillips, flathead, Torx, etc.) are worn down to the point where tools can no longer grip effectively.

This damage often happens gradually, but once stripped, the screw becomes significantly harder to remove.

Common Causes of Stripped Screws

• Incorrect Tool Size

Using a screwdriver that doesn’t match the screw head causes slippage and damage.

• Excessive Force

Applying too much torque overwhelms the screw head’s strength.

• Low-Quality Screws

Cheap screws are often made of softer metals.

• Power Tool Misuse

High-speed drills can strip screws instantly.

• Corrosion or Rust

Metal degradation weakens grip surfaces.

• Soft Base Materials

Plastic or wood can deform, increasing resistance.

Understanding these causes helps prevent future stripping while guiding the best removal strategy

Also Read : How to Use a Compass: A Complete Guide for Beginners and Kids

How to Remove a Stripped Screw with a Screwdriver (Basic Methods)

Many people search how to remove a stripped screw with a screwdriver because they want a solution without specialized tools. In many cases, this is possible with proper technique and patience.

This approach focuses on restoring grip or increasing friction.

Screwdriver-Only Techniques Explained

• Use the Correct Size and Type

Switching to a slightly larger or different screwdriver (Phillips to flathead) can create new grip points.

• Apply Downward Pressure

Firm, steady pressure prevents cam-out and increases friction.

• Angle Adjustment

Tilting the screwdriver slightly can help it bite into remaining grooves.

• Manual Rotation Only

Avoid power tools to maintain control and prevent further damage.

• Tap the Screwdriver In

Light hammer taps seat the tool deeper into the head.

• Slow, Controlled Turns

Small movements reduce the risk of full head failure.

This method works best when the screw is only partially stripped.

Also Read : How to Quit a Job: A Complete Guide to Leaving Gracefully

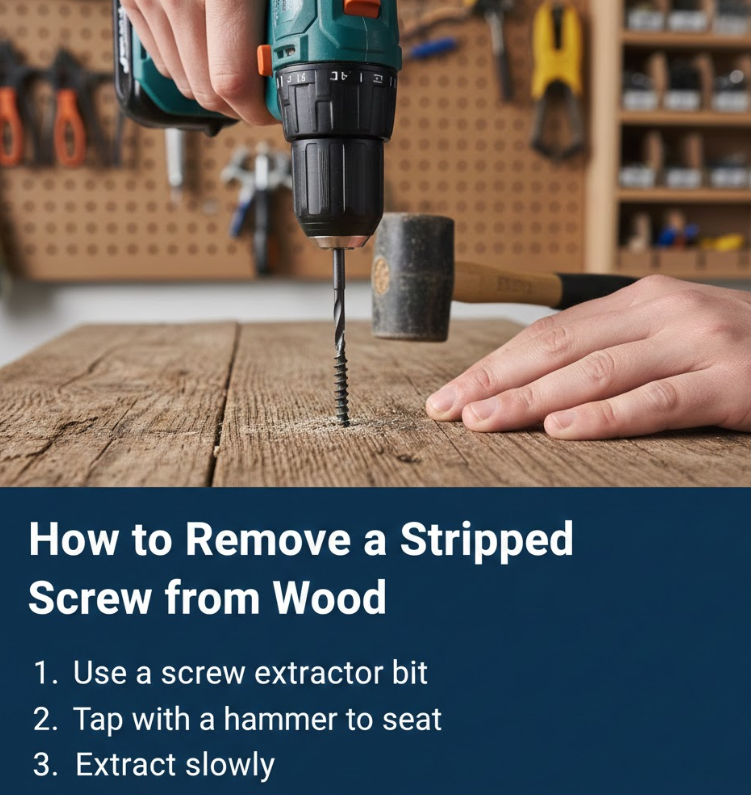

How to Remove a Stripped Screw from Wood

Learning how to remove a stripped screw from wood requires extra care because wood is soft and easily damaged. The goal is to remove the screw without enlarging the hole or splitting the wood.

Wood screws often strip when overtightened or when driven into hardwood without pilot holes.

Wood-Specific Removal Techniques

• Back the Screw Out Slowly

Apply constant pressure and rotate slowly to prevent tearing wood fibers.

• Grip the Screw Head (If Exposed)

Use locking pliers if the head protrudes slightly.

• Cut a New Slot

A rotary tool can create a flathead groove.

• Leverage the Wood Slightly

Gentle prying while turning can reduce friction.

• Protect the Surface

Use cardboard or tape to prevent tool marks.

• Repair the Hole After Removal

Wood filler or dowels restore structural integrity.

Patience is critical when working with wood to avoid permanent damage.

Also Read : How to Fix a Running Toilet: A Complete Step-by-Step Guide

How to Remove a Stripped Screw from Metal

Understanding how to remove a stripped screw from metal is more challenging due to hardness, corrosion, and tighter thread engagement.

Metal screws often seize due to rust or heat expansion.

Metal-Focused Removal Methods

• Penetrating Oil Application

Lubricants reduce friction and break corrosion bonds.

• Heat Expansion Technique

Gentle heat causes metal expansion, loosening threads.

• Hammer-Tap Method

Sharp taps help break rust and re-seat the tool.

• Extractor Tools

Screw extractors bite into the damaged head.

• Reverse Drill Bits

Drilling counter-clockwise can spin screws out.

• Thread Protection Awareness

Avoid over-drilling to preserve internal threads.

Metal removal often requires patience and staged attempts.

Also Read : How to Get Rid of Drain Flies: Complete Expert Guide

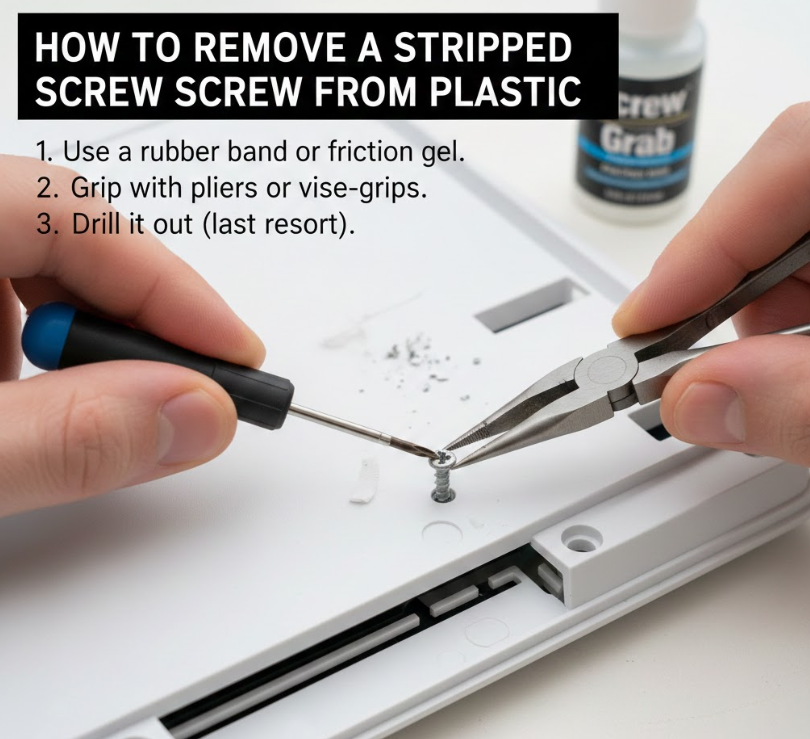

How to Remove a Stripped Screw from Plastic

Knowing how to remove a stripped screw from plastic requires a delicate approach. Plastic strips easily and can crack if stressed improperly.

This scenario is common in toys, appliances, and consumer electronics.

Plastic-Safe Removal Techniques

• Low Torque Only

High force will destroy surrounding plastic.

• Grip Enhancement Methods

Rubber bands or valve grinding compound increase traction.

• Minimal Heat Usage

Excessive heat melts plastic.

• Lift While Turning

Upward tension reduces thread friction.

• Avoid Drilling Unless Necessary

Drilling risks cracking thin housings.

• Reinforce After Removal

Epoxy or thread inserts restore holding strength.

Plastic demands precision and restraint above all else.

Also Read : How to Endorse a Check: The Complete Step-by-Step Guide

How to Remove a Stripped Screw from a Laptop or Electronics

Searching how to remove a stripped screw from a laptop is extremely common—and risky. Electronics screws are tiny, soft, and surrounded by sensitive components.

Improper techniques can destroy circuit boards or casings.

Electronics-Safe Screw Removal

• Use Precision Tools Only

Micro screwdrivers reduce accidental damage.

• ESD Precautions

Static discharge protection is essential.

• Rubber Grip Method

Thin rubber sheets increase screwdriver traction.

• Exact Fit is Critical

Even slight size mismatches cause stripping.

• Controlled Pressure

Apply force vertically, not sideways.

• Know When to Stop

Forcing screws risks motherboard damage.

If resistance remains, professional repair may be safer.

Also Read : How to Make Oobleck: The Complete Science-Backed Guide for Kids and Adults

Why Screw Extractors Work (And When They Don’t)

Screw extractors are often recommended for how to remove a stripped screw, but they are not always the best solution.

Understanding their mechanics prevents misuse.

Screw Extractor Insights

• Reverse Thread Design

Extractors bite harder as you turn counter-clockwise.

• Requires Drilling First

Incorrect drilling depth ruins effectiveness.

• Brittle Tool Material

Extractors can snap if forced.

• Best for Metal Screws

Less effective in plastic or wood.

• Alignment Matters

Off-center drilling causes breakage.

• Patience Over Power

Slow, steady rotation is key.

Extractors work best when used cautiously.

Also Read : How to Cancel Kindle Unlimited: The Complete Step-by-Step Guide

Preventing Stripped Screws in the Future

Learning how to remove a stripped screw is valuable—but preventing them saves time and frustration.

Prevention Best Practices

• Use Correct Tool Sizes

Match screw heads exactly.

• Pre-Drill Pilot Holes

Reduces driving resistance.

• Manual Finish Tightening

Avoid over-torquing with power tools.

• Quality Hardware Investment

Stronger screws strip less.

• Lubricate Metal Screws

Reduces friction during installation.

• Stop at First Slip

Slipping is a warning sign.

Conclusion

Mastering how to remove a stripped screw transforms frustrating repairs into manageable tasks. Whether the screw is embedded in wood, metal, plastic, or a delicate laptop casing, the right technique—and patience—makes all the difference.

By understanding why screws strip, choosing appropriate tools, and applying controlled methods, you can safely remove damaged screws without harming surrounding materials. With practice, even the most stubborn stripped screw becomes solvable.

FAQs

Can I remove a stripped screw without special tools?

Yes, in many cases using grip techniques and patience.

Is drilling always necessary?

No—drilling is a last resort.

When should I stop and seek professional help?

If working on electronics or structural components at risk

Visit For More Information Go To entrepreneurideas